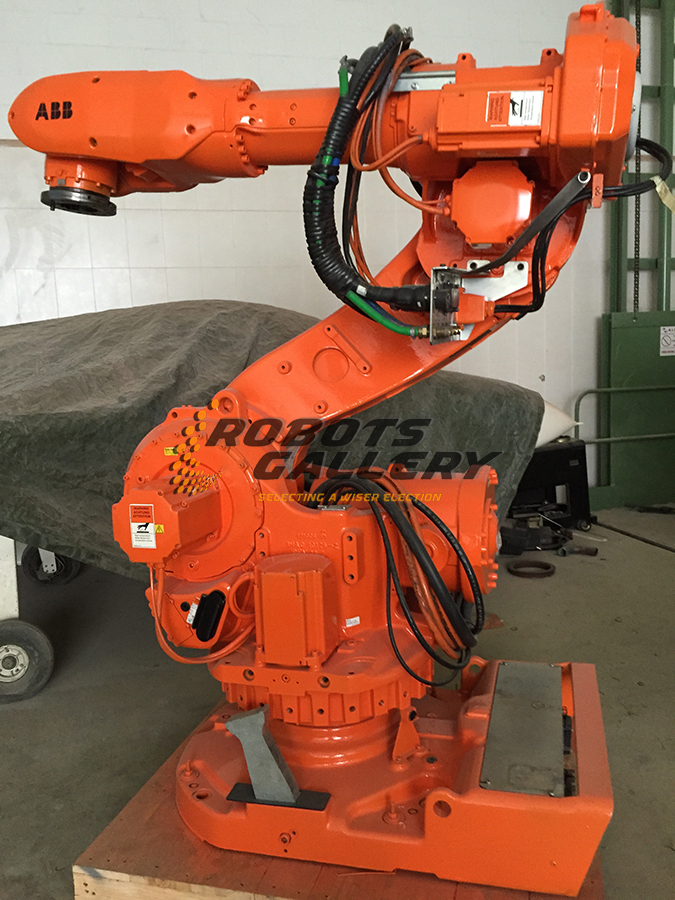

IRB 6600 IRC5 M2004

Technical Data

- Payload: 0/175 Kg

- Arm reach: 2.55 mm

- Number of Axis: 6

- Repeatability: 0.10 mm

- Robot weight: 1700 Kg

- Mounting: Floor

Technical Data:

• Payload: 175 Kg

• Maximum Reach: 2550 mm

• Repeatability: 0.1 mm

• Controller: IRC5 M2004

Axis motion speed

• Axis 1: 100º/s

• Axis 2: 90º/s

• Axis 3: 90º/s

• Axis 4: 150º/s

• Axis 5: 120º/s

• Axis 6: 190º/s

Robot Applications

• Spot welding

• Press tending

• Material handling

• Machine tending

• Palletizing

• Assembly

• Payload: 175 Kg

• Maximum Reach: 2550 mm

• Repeatability: 0.1 mm

• Controller: IRC5 M2004

Axis motion speed

• Axis 1: 100º/s

• Axis 2: 90º/s

• Axis 3: 90º/s

• Axis 4: 150º/s

• Axis 5: 120º/s

• Axis 6: 190º/s

Robot Applications

• Spot welding

• Press tending

• Material handling

• Machine tending

• Palletizing

• Assembly

Applications

IRB 6600 IRC5 M2004

YEAR 2005-2007 The ABB IRB 6600 robot is still very rare on the used market as most are still employed in their first application. The 6600 is the successor to the IRB 6400 range.The 6600 is used in many car factories around the world and has a good reputation for being fast, strong and flexible. The 6600 can be used in many applications including pick and place, machine tending, grinding, welding, de-burring, trimming, and sealing. The ABB IRB 6600 models were first supplied with the ABB M2000 S4C+ controller, but more recently this has been superseded by the M2004 IRC5 controller. Video